Automobile Inspection Tools are Different Due to the Size of Automobile Structure

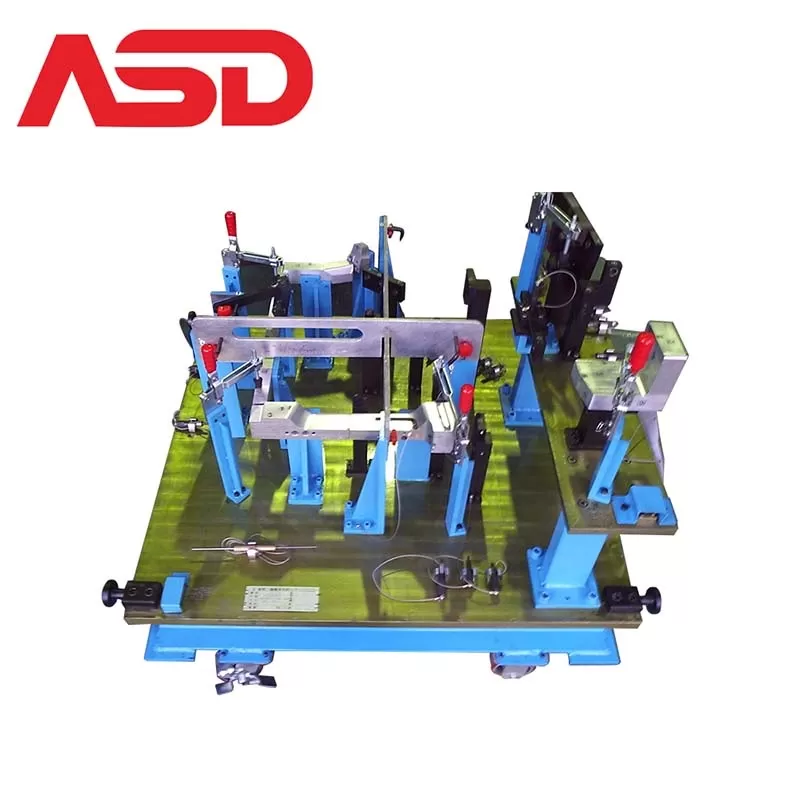

1. The die for small stamping parts of automobile body is mainly composed of bottom plate assembly, clamping device group, inspection body, main and auxiliary positioning pins and section template, etc. The main elements to be inspected are the position of the workpiece shape (including the contour of the workpiece and the shape of the curved surface, etc.) characterized by holes and flanges. When designing small sized automobile inspection tools, the dimension datum is usually placed in the body coordinate system, coordinate lines are drawn every 100mm in X, Y, Z Y and Z directions, and the coordinate system of inspection tools is established by reference blocks and reference holes on the base plate.

2. Most of the body stamping parts have spatial curved surfaces and many local features, and are characterized by non-axial symmetry and poor rigidity, so it is difficult to locate, support and clamp. At present, most of the body stamping parts are inspected by numerical control machine tools according to the numerical model and the predetermined processing procedure, and all the surfaces and hole positions to be machined are automatically completed at one time. Most of the inspection materials for small cars are epoxy resin. After the design of automobile inspection is completed, the position and size of the bottom plate assembly shall be determined according to the automobile inspection tools, and section templates shall be set at the key sections to be inspected.