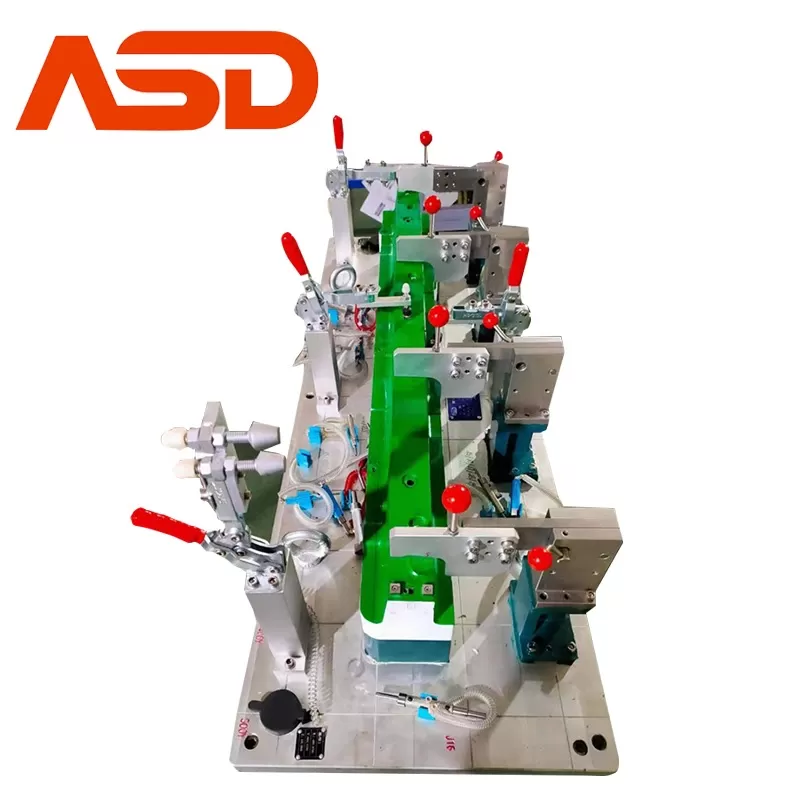

Composition of Automobile Inspection Tools

Automobile inspection tools usually consist of the following three parts:

1. Skeleton and base.

The framework and base of the detector are usually made of aluminum plate or steel plate in the manufacturing process. The function of the bottom plate is to provide an assembly platform to strengthen its positioning and detection. On the base of the detector, a detection reference is provided to provide the accuracy of the detector itself. The detection reference points can be blocks, holes or spherical reference points, which are usually placed on the four corners of the bottom plate. The required interval is usually a multiple of 100, and they are placed on a reference plate for easy display.

2. Measuring surface

By installing a detection surface, you can check the edges and cross sections of all parts of the car body. The measurement range includes: detecting the clearance surface and the surrounding cutting lines, usually the distance between the measurement surface and the measured part surface is 5mm or 3mm [1]. Alignment detection: the alignment direction is usually defined as the standard direction of a piece of edge shape. The size of the zero detection surfaces is guaranteed to be more than 30mm.

3. Functional parts Functional components include quick clamp, detection pin, marking pin and positioning pin. The function of positioning pin is to ensure that the object being inspected is accurately positioned on the inspection device, and the position of positioning hole is determined according to the 2D pattern of the object. The working state of the main positioning pin and the secondary positioning pin ensures that the measured object will not shake after positioning. The detection pin is used to detect the tolerance of the relevant aperture. If there are multiple holes on the part to be measured, and their diameters and position tolerances are the same, it is usually only necessary to manufacture a single inspection pin. If the availability of the inspection tool is met, the function of clamping and fixing device is to ensure the stability of the inspected part, so as to obtain the correct inspection result. According to the 2D drawing requirements of the inspected part, the inspected position should be reasonably selected without affecting the inspection function. The fixing device is usually directly inserted into the bottom of the inspection tool or connected by welding or melting.