Factors to Be Considered In the Design and Manufacture of Automobile Inspection Tools and Design Steps and Processes

Automobile inspection tool is a simple tool used by industrial production enterprises to control various sizes of products (such as aperture, space size, etc.) to improve production efficiency and control quality. It is suitable for mass-produced products, such as automobile parts, to replace professional measuring tools, such as smooth plug gauge, threaded plug gauge, outside diameter caliper gauge, etc. So, what factors should be considered when designing automobile inspection tools?

I. Design concept Design and manufacture of automobile checking fixture before checking fixture design, the concept of checking fixture design should be defined, and the following factors should be fully considered:

1.1 Fully understands GD&T GD&T is a descriptive document of automobile product design. Product specifications, product positioning standards, key product characteristics (KPC) and product tolerance characteristics will all be reflected in GD&T. Therefore, it is necessary to fully understand GD&T before designing the fixture.

1.2 Determine the product positioning and testing content. On the basis of full understanding of product GD&T, this paper analyzes the characteristics of product positioning datum, considers the placement position of product parts, understands the meaning of various tolerances, and determines the testing contents that product parts must realize on the fixture and the contents that do not need to be realized or even cannot be realized at all.

1.3 statistics of process control capability (SPC) Identify whether the product has KPC requirements or not, know the use of checking tools in CNC precision mould making, correctly understand the needs of quantitative measurement and qualitative measurement, and ensure the reliability of SPC data acquisition.

1.4 Understand requirements and processes fully understand the customer’s demand for product inspection tools, learn from previous successful or failed cases, fully understand the process of customer inspection tool review and approval, and understand the required documents.

II. The design principle The fixture should have sufficient rigidity; Should have sufficient stability; Should have enough measurement accuracy to ensure the quality of the car; Operation should be convenient to ensure sufficient measurement efficiency; The structure should be as simple as possible; Should have a good appearance; Should have enough economic guarantee to facilitate the control of the whole vehicle cost; At the same time, it should be convenient for measurement and calibration.

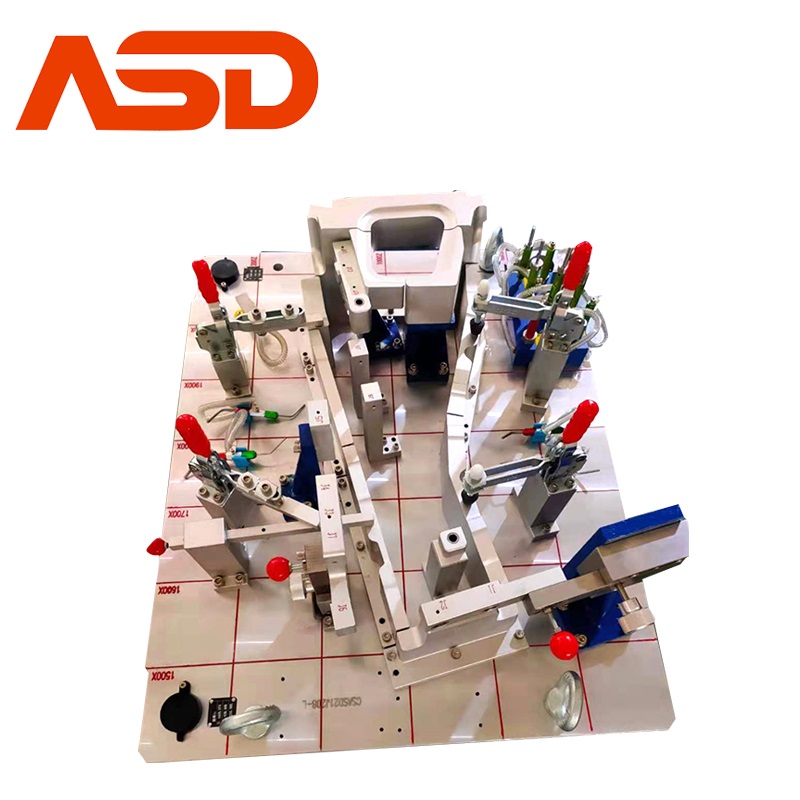

III. The design points of large-scale decorative parts inspection tools. The inspection of large-scale automobile accessories has the commonness of automobile parts inspection tools, and also has its own characteristics. Its structure is mainly composed of the following parts: base plate and frame, positioning device, clamping device, measuring device, auxiliary device, etc.

IV. Steps of designing and manufacturing automobile inspection tools

1. It is necessary to analyze the workpiece with reference to the part drawings, preliminarily draw up the design scheme of the checking fixture, determine the datum plane, concave and convex conditions of the checking fixture, detect the cross section, positioning surface, etc., and simply draw its two-dimensional schematic diagram.

2. Design and modeling, which directly affects whether the fixture can accurately detect the quality of the workpiece. Because the body panel is mainly free-form surface, “physical reverse engineering” is a general modeling method at present. Reverse engineering refers to the method of building a prototype model with a specific shape and structure according to the existing workpiece or physical prototype, using a laser scanner to collect data, and through data processing, three-dimensional reconstruction and other processes, using the method of automobile fixture.

3. Sweep the standard workpiece surface with a laser scanner, collect the feature information of the workpiece surface mainly based on point clouds, and convert the point coordinates to the vehicle body coordinates.

4. Use surfacer software to process the point information, and get the characteristic curve of the workpiece surface, so as to generate the final free-form surface model.

5. At the same time, the generated prototype model can be detected by the distance from the point cloud to the curved surface. At this time, the obtained model is a sheet model with no thickness. It is particularly important to identify the model as the inner or outer surface of the workpiece according to the surface scanned by the scanner. Therefore, in the process of designing and manufacturing automobile inspection tools, in addition to fully considering all factors of inspection tools, we should also make them according to the actual operation process, and control every link of designing and manufacturing automobile inspection tools layer by layer, so that the structure of automobile inspection tools is consistent with the sample.